T-squares are essential tools in maintaining straight and parallel lines in technical drawings due to their design and functionality. Here's how they assist in achieving precision:

Fixed Straight Edge Precision: The manufacturing precision of the fixed straight edge involves state-of-the-art techniques such as CNC machining or laser cutting. Materials undergo rigorous testing for dimensional stability and thermal expansion. T-squares often undergo secondary processes like anodization to enhance surface hardness and corrosion resistance, ensuring a long-lasting, impeccably straight edge for meticulous technical drawings.

Parallel Ruler Functionality: The parallel ruler functionality is achieved through the integration of advanced gliding mechanisms. Some T-squares employ ball bearings, while others may use self-lubricating materials to ensure smooth motion. Engineers consider factors like friction coefficients and wear resistance, implementing designs that provide not only parallel movement but also a satisfying, effortless glide, enhancing the user experience during prolonged drafting sessions.

Stability for Reliable Results: Stability is a multifaceted aspect involving anti-skid features, weight distribution, and structural integrity. High-end T-squares utilize non-slip materials strategically placed on the underside, minimizing any chance of slippage. The weight distribution is optimized to balance sturdiness with ease of handling. Structural reinforcement may include internal bracing or composite materials, ensuring that the T-square maintains its stability even under varying pressures and conditions.

Consistency in Angles: Achieving consistent angles demands meticulous design of the angle adjustment mechanism. Premium T-squares may incorporate locking systems that engage with satisfying clicks, providing tactile feedback to the drafter. The engineering precision extends to angle markings, with laser-etched graduations ensuring accuracy down to minute details. This level of sophistication is crucial for professionals who demand not just precision but a tactile assurance of it.

Versatility in Size: The versatility in T-square sizes extends beyond length considerations. Engineers evaluate the optimal balance of weight, rigidity, and material characteristics for each size variant. Longer T-squares may feature reinforced internal structures or additional bracing to counteract potential flexing. Size-specific considerations contribute to a holistic approach to versatility, ensuring that each T-square meets the demands of its intended application with utmost efficiency.

Horizontal and Vertical Alignment: The engineering of T-squares for seamless horizontal and vertical alignment involves sophisticated pivot mechanisms. Engineers meticulously design these pivots to maintain precision and rigidity, ensuring that the T-square doesn't introduce unintended variations in alignment when transitioning orientations. This engineering excellence guarantees that professionals can confidently switch between drawing orientations without compromising accuracy.

Ease of Use and Accessibility: User-friendly design goes beyond ergonomic considerations; it encompasses tactile feedback, intuitive controls, and thoughtful features. T-squares may incorporate grips with anti-fatigue properties for extended use. Engineers design control elements with a focus on intuitive operation, reducing the learning curve for users. Clear, high-contrast markings contribute to enhanced visibility, ensuring that drafters can work with precision even in demanding conditions.

Reference Edge for Precision: The reference edge undergoes meticulous calibration and quality control processes. Manufacturers employ advanced metrology tools to validate the straightness and accuracy of this critical component. Precision laser etching ensures that measurements are not only accurate but also clearly visible. The reference edge serves not just as a guide for drawing but as a benchmark for the entire drawing process, aligning other tools with an unmatched level of precision.

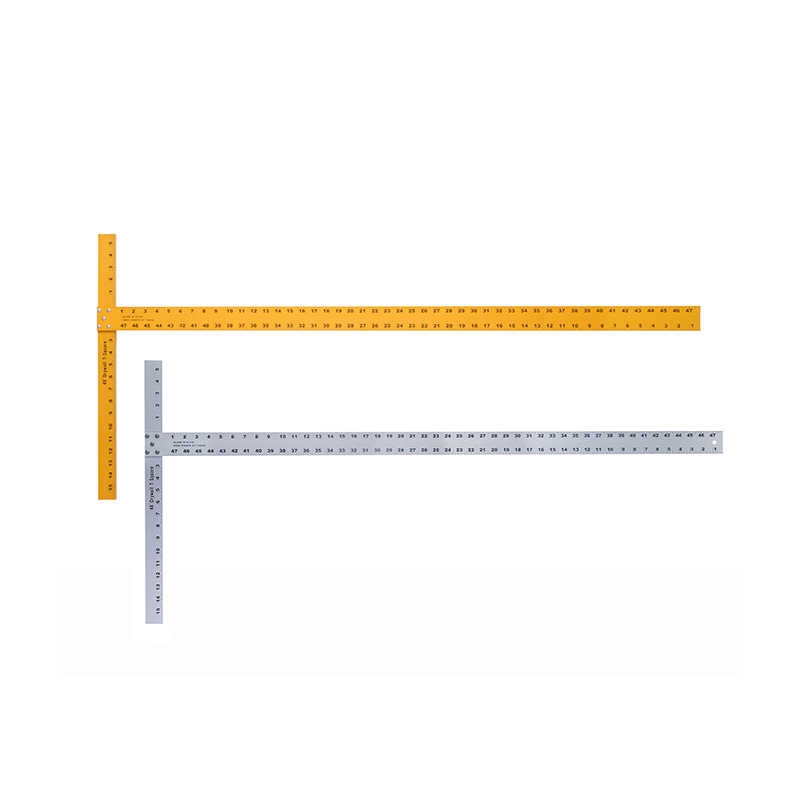

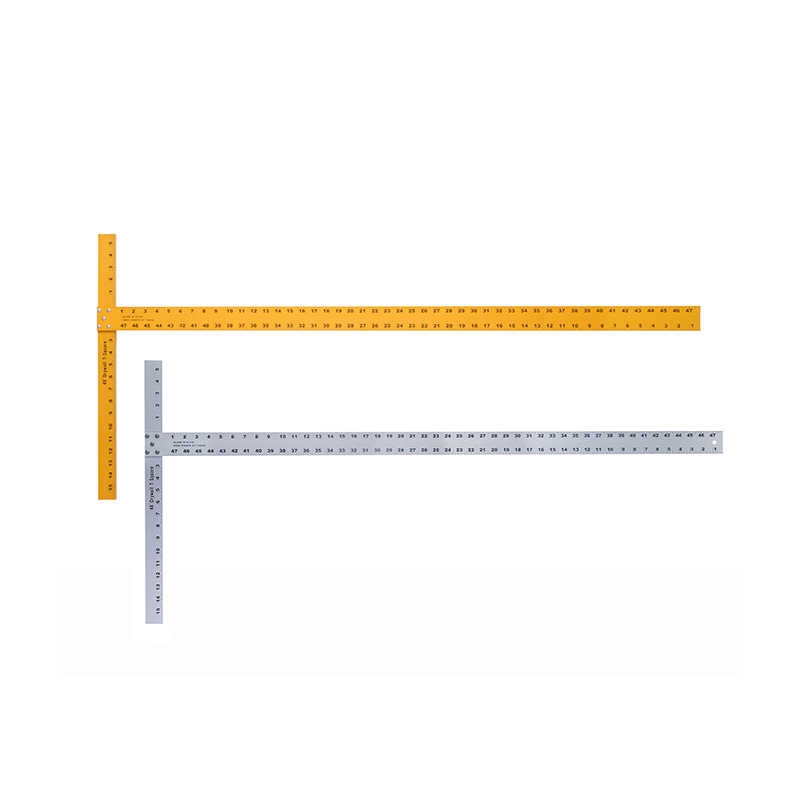

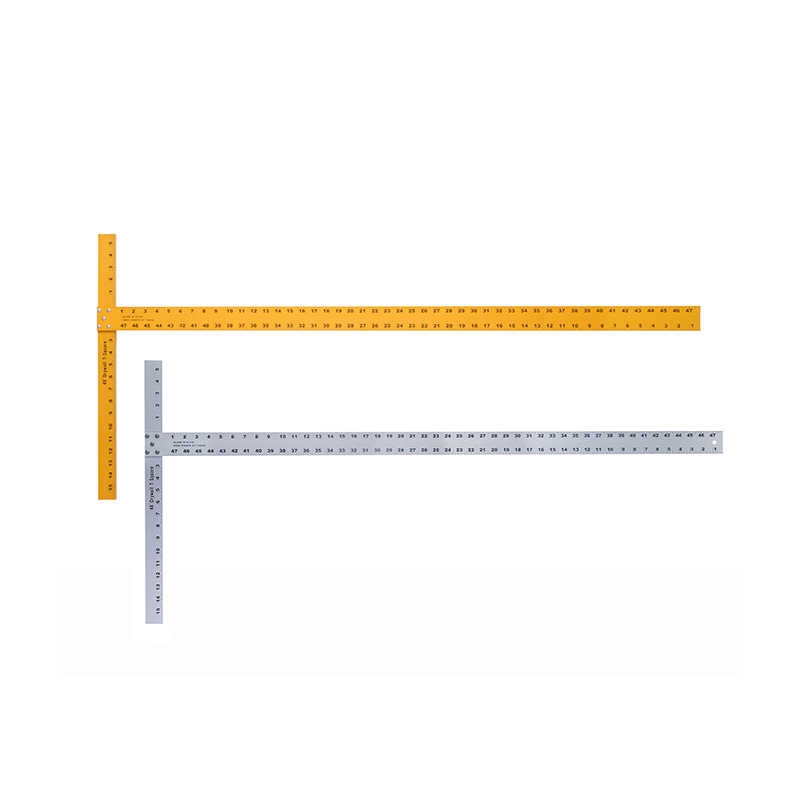

Aluminium Drywall T-square