2. Key Features and Functions of Digital Calipers for Accurate Measurements

Measurement Modes: Digital calipers offer multiple measurement modes, including inside, outside, depth, and step measurements. These modes allow users to measure various dimensions accurately, providing flexibility and versatility in different applications.

Precision and Accuracy: Digital calipers typically have high precision and accuracy levels, often ranging from ±0.001 inches (0.02mm) to ±0.0005 inches (0.01mm). This level of accuracy is essential in industries where precise measurements are crucial for meeting specific tolerances and quality standards.

Zero Setting and Hold Function: Digital calipers feature a zero-setting function that allows users to establish a reference point for relative measurements. Additionally, the hold function enables users to freeze and retain a measurement value on the display, even after removing the caliper from the object being measured.

Conversion Capability: Many digital calipers can perform metric-to-imperial or imperial-to-metric conversions, providing convenience for users who work with different measurement systems or need to convert between units frequently.

Data Output: Advanced digital calipers may have data output capabilities, allowing measurements to be transmitted directly to a computer or data collection system. This feature streamlines data management, enhances efficiency, and facilitates data analysis and documentation.

3. Applications and Benefits of Digital Calipers in Various Industries

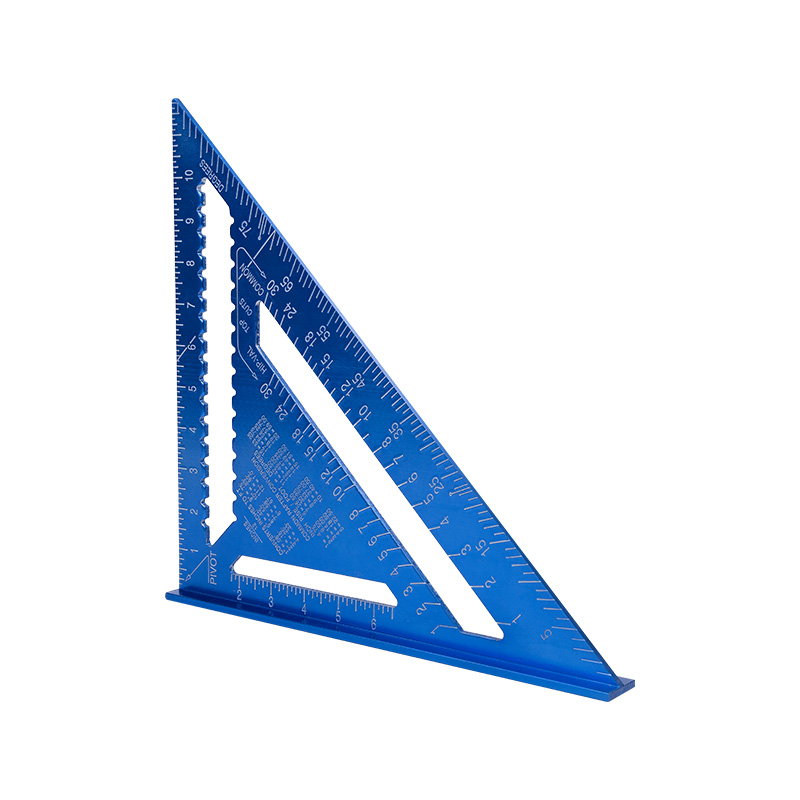

Woodworking and Carpentry: In woodworking applications, digital calipers enable precise measurements for cutting, shaping, and joinery. They ensure accurate dimensions for furniture, cabinetry, and other wooden structures, leading to better craftsmanship and improved aesthetics.

Automotive and Aerospace: Digital calipers play a critical role in the automotive and aerospace industries, where precision and quality control are paramount. They are used for measuring components, engine parts, fasteners, and other critical elements, ensuring proper fit, performance, and safety.

Research and Laboratories: In scientific research, digital calipers are utilized for dimensional analysis, material testing, and sample measurements. Their accuracy and ease of use make them valuable tools in laboratories and research facilities.

The benefits of digital calipers in these industries include improved measurement accuracy, time savings, ease of use, and the ability to capture and store data for documentation and analysis.

English

English Español

Español